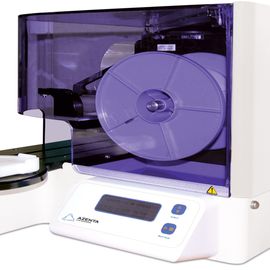

Azenta introduces automated plate seal remover to enhance laboratory efficiency

Azenta Life Sciences has launched an innovative solution addressing a common laboratory bottleneck. The Automated Plate Seal Remover offers single-touch operation for efficiently removing seals from microplates without damage, providing significant time-saving benefits for high-throughput environments whilst maintaining sample integrity and reducing contamination risks.

Novel design eliminates mechanical failure points

The system employs a patented de-sealing mechanism that differentiates it from conventional options. Each plate passes under a freshly exposed section of de-sealing tape, which adheres to and gently lifts away the seal. This distinctive approach eliminates mechanical removal components that frequently malfunction in traditional systems.

The device securely stabilises plates during processing, ensuring consistent removal performance “even for the most stubborn seals,” according to product documentation.

Significant workflow improvements for high-volume laboratories

For laboratories processing numerous microplates, manual seal removal creates a substantial efficiency barrier. Even facilities invested in automated liquid handling or robotic storage systems often face this persistent manual bottleneck.

The Automated Plate Seal Remover delivers “precise, automated peeling” that eliminates “tedious, time-consuming manual removal” whilst reducing cross-contamination risk from sample run-off. With capacity to process up to 200 plates hourly, the system accelerates workflows and liberates valuable research time.

Integration capabilities for complete automation

Whilst functioning effectively as a standalone unit, the system truly excels when incorporated into existing robotic workflows. Integration transforms the device into a “fast, reliable, walk-away solution” that enhances overall laboratory productivity. The compact design facilitates placement within space-constrained laboratory environments without sacrificing performance. The system accommodates diverse microplate formats, providing flexibility across multiple research applications.

Protecting sample integrity

Beyond efficiency gains, the automated approach helps “protect sample integrity and minimize degradation by reducing time spent on the benchtop.” This represents a significant advantage for temperature-sensitive or environmentally vulnerable samples where processing speed directly impacts experimental outcomes.

For more information, visit: https://www.azenta.com/products/automated-plate-seal-remover-formerly-xpeel

Digital issue: Please click here for more information