Researchers develop precision droplet-on-demand system for microfluidics

A new pressure-driven method for generating individual droplets at microfluidic T-junctions offers precise temporal control over droplet formation. The technique, validated through theoretical modelling and experimental testing, promises to advance lab-on-a-chip technologies for chemical analysis, diagnostics, and biological research applications.

Researchers from the University of Glasgow and the Changchun Institute of Optics have developed an innovative approach to microfluidic droplet generation that transforms traditionally unpredictable systems into programmable, precision-controlled platforms. The work, published in Microsystems & Nanoengineering, addresses longstanding challenges in droplet microfluidics where real-time manipulation of individual droplets has remained elusive.

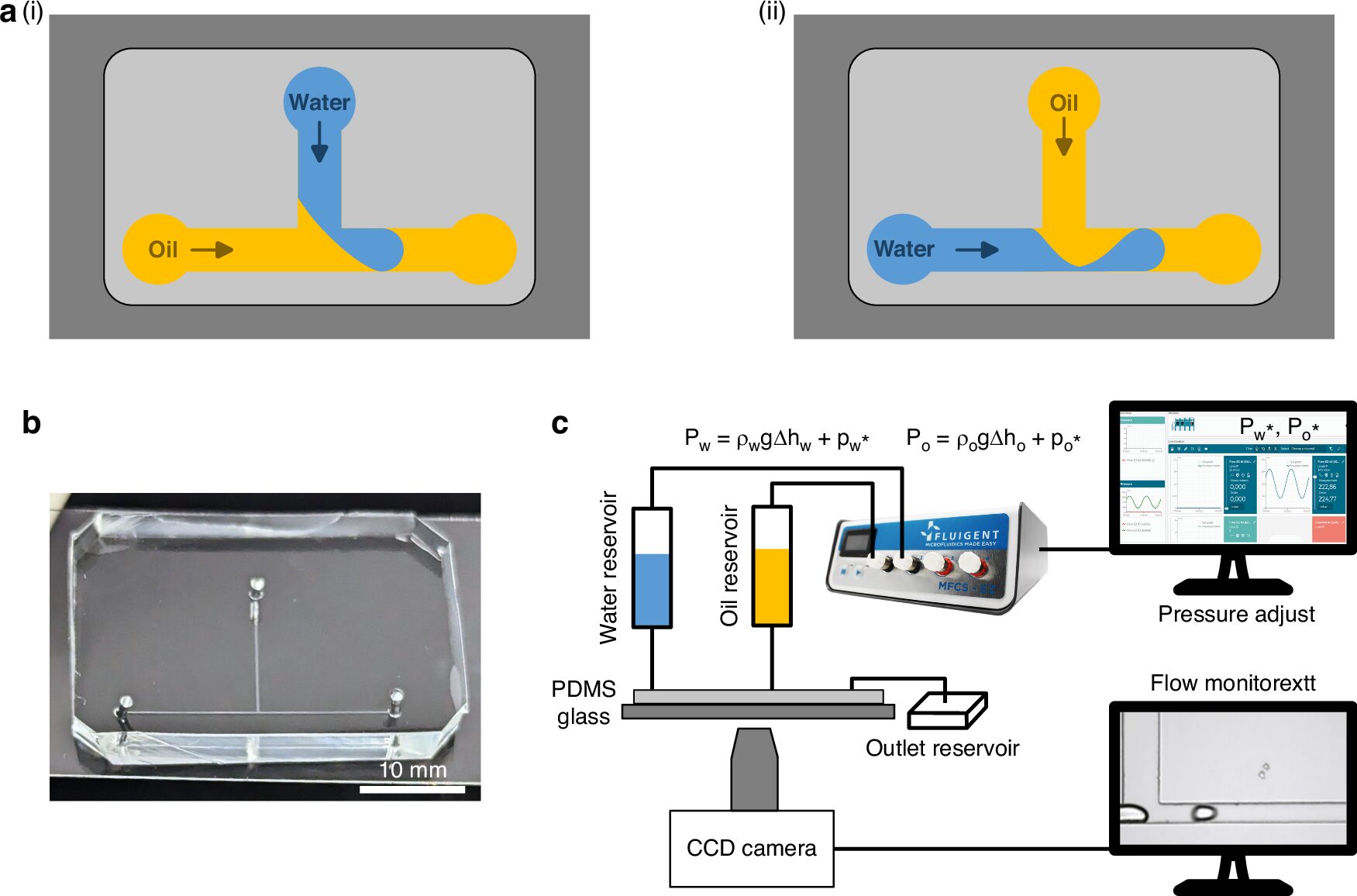

Inverting traditional approaches

The breakthrough lies in a fundamental redesign of the classic T-junction configuration. Rather than allowing water to be sheared off by oil flow in the conventional arrangement, the researchers introduced oil through the side channel, enabling it to intercept and slice the water stream with guillotine-like precision under controlled pressure conditions.

“Our aim was to make droplet microfluidics smarter, not harder,” said Professor Huabing Yin, the study’s senior author. “We’ve shown that with a straightforward change in geometry and a bit of physics, we can turn a previously unpredictable system into one you can program and control. That’s a game-changer for labs looking to automate and scale up.”

This geometric inversion, combined with theoretical modelling grounded in capillary physics, enables researchers to accurately predict when droplets will form or cease formation based on inlet pressures and channel geometry. The team validated their approach across various device configurations and surfactant-modified oils, demonstrating robust performance across different experimental conditions.

Theoretical framework and validation

The researchers developed a comprehensive physical model using classical Laplace-Young capillary pressure equations to describe the mechanism underlying droplet generation. The model defines two critical pressure thresholds: an upper threshold above which oil pressure prevents water from entering the T-junction, and a lower threshold below which oil cannot interrupt continuous water flow.

The study showed excellent agreement between theoretical predictions and experimental observations across multiple device geometries. For devices with channel heights ranging from 32 to 75 micrometres and varying channel widths, the model successfully predicted pressure thresholds required for switching droplet generation on and off.

The authors noted in their discussion that “the ability to predict threshold conditions for on-demand droplet formation in T-junction devices allows active and automated control of droplet formation at the individual droplet level, greatly enhancing practicability and reliability.”

Addressing real-world complexities

Recognising that surface tension variations and other real-world inconsistencies could affect system performance, the researchers developed a visual feedback method. This approach tracks droplet generation frequency to fine-tune pressure settings in real-time, expanding operational flexibility without requiring complex instrumentation.

The team observed a parabolic relationship between droplet generation frequency and oil pressure, which enabled development of an in situ optimisation method. By fitting experimental data to this relationship, researchers can determine pressure thresholds even when nominal parameters are uncertain due to surface treatments or surfactant modifications.

Practical implementation

The system demonstrated precise control sufficient to generate single droplets at timed intervals – a capability essential for applications such as cell encapsulation and timed reagent delivery. Tests showed the system worked reliably across different designs, with droplet volumes controllable through pressure adjustment within predicted ranges.

The researchers successfully implemented on-demand droplet formation by connecting the oil inlet to two reservoirs via a valve system, enabling rapid switching between ‘on’ and ‘off’ states. Time-series imaging confirmed reliable generation of individual water-in-oil droplets with well-defined intervals between successive droplets.

Broad applications and implications

The innovation addresses critical limitations in current microfluidic approaches. Passive droplet generation methods, while offering high throughput, provide limited control over individual droplet formation and content. Cell encapsulation using passive methods follows a Poisson distribution with very low single-cell encapsulation rates. Active methods requiring external forces add complexity to device fabrication and instrumentation.

The authors emphasised that their findings “offer valuable guidelines for the design and automation of robust droplet-on-demand microfluidic systems, which can be readily implemented in conventional laboratories for a broad range of applications.” The low barrier to implementation – requiring no external fields or complex electronics – makes the system particularly attractive for portable or point-of-care devices.

Future prospects

The research opens new possibilities for programmable microfluidic platforms across multiple fields. From biomedical diagnostics to synthetic biology, any application requiring precise fluid handling could benefit from this model-guided droplet system. The ability to customise droplet size and timing enables researchers to design microfluidic systems tailored to specific experimental requirements.

As laboratories continue to miniaturise and automate processes, this innovation could become a cornerstone of next-generation lab-on-a-chip platforms.

Reference:

Zhao, H., Mills, W., Glidle, A., et. al. (2025). On-demanddroplet formation at a T-junction: modelling and validation.

Microsystems & Nanoengineering, 11, 94.

https://doi.org/10.1038/s41378-025-00950-2

Pressure-Driven droplet formation at a microfluidic T-junction.

a Schematic diagram of a T-junction microfluidic device used for droplet generation (not to scale). (i) example where water is in the side channel and the droplet is ‘sheared-off’ by oil flow; (ii) example where oil is in the side channel (this work) and the droplet is ‘cut-off’ by oil flow pressure increase after traversing the T-junction. b Photograph of the T-junction microfluidic device. c Schematic diagram of the experimental setup. A Fluigent pressure pump is used for pressure adjustment. The total pressures of oil (Po) and water (Pw) at the oil and water reservoir are the sum of the hydrostatic pressure ρOgΔhO and ρWgΔhW and the pressure from the pressure pump Pw, Po, respectively. Here, ρ, g and Δh denote the density, gravitational acceleration and the height difference from the top of the liquid reservoir to the height of the microchip.